3D PRINTING Service BY LASER LINES LIMITED

Fast And Reliable Service

For High-Quality 3D Printed Parts For Your Business

Get your quote today!

What to expect from our service?

Quick turnaround time

90% parts shipped within 3 days with 1 day delivery

Experience

Over 10 000 3D Printed parts!

Expertise

We can help you save up to 60% on cost per part

Quality and safety

ISO 9001:2015 and JOSCAR Accredited

.jpg?width=2000&height=1338&name=kumpan-electric-fJebhGIP0P4-unsplash%20(1).jpg)

You Design, we 3D Print!

Our bureau service has grown over the years and supplied quality parts to many industries. We have expanded our in-house capacity to the latest machines, to ensure we can offer the best to our customers. A quotation can be supplied the same day and parts typically shipped within a few days.

With over 20 in house printers, we can provide anything from a single print to large-scale production, depending on your needs. Our fleet includes the best from the Stratasys range: Fortus 900mc, F3300, F770, Fortus 450mc, PolyJet J850, PolyJet J55, and F370 CR.

High quality and reliable parts – every time!

FDM is one of the most common 3D printing technologies, utilising thermoplastic filaments where a moulten bead of material is extruded layer by layer.

Advantages:

-

Cost-effective and widely available.

-

Offered with a wide range of materials.

-

Used for prototyping and functional parts.

- Ideal choice for jigs and fixtures

A popular choice for a large variety of applications, where robust material properties are needed.

SLA is one of the oldest 3D printing technologies and relies on a laser to scan the surface layer of a resin. After each layer has been cured, the Z stage steps down into the vat, while a new layer of resin is recoated on top to be cured. As with other resin technologies, the parts need to be washed and cleaned once removed from the machine, then cured in a UV oven.

-

Advantages:

-

High accuracy and repeatably process

-

Smooth surface finish.

- For large, single piece parts

-

Capable of producing complex geometries.

-

For reliable and repeatable results.

In Polyjet machines, a photosensitive epoxy resin is inkjet-printed and simultaneously cured by a UV lamp, allowing for multi-material and multi-colour parts.

Advantages:

- Multi material printing

- Full colour ‘Pantone’ validated

- Fine feature detail

- Ideal product realism

For those that need smooth surfaces, fine feature detail and potentially full colour.

SAF (selective absorption fusion) process involves melting the pre-heated powder into a solid form using infrared light source.

Advantages:

- Cost-effective and reliable.

- Suitable for a batch production of small and medium parts.

- Good for end production parts.

- Allows printing of working assemblies

Production-level throughput for end-use parts

This resin-based technology offers huge flexibility for users, creating parts with an excellent surface finish that have great engineering properties and excellent finish.

Advantages:

- Excellent mechanical properties

- Fine feature detail

- High accuracy

- Smooth surface finish

- Large choice of resins available

Which is the best 3D Printing technology for my project?

There are a bewildering number of additive manufacturing technologies available to businesses today. All of them have their pros and cons. Use this graph to assess which technology is best suited for your application.

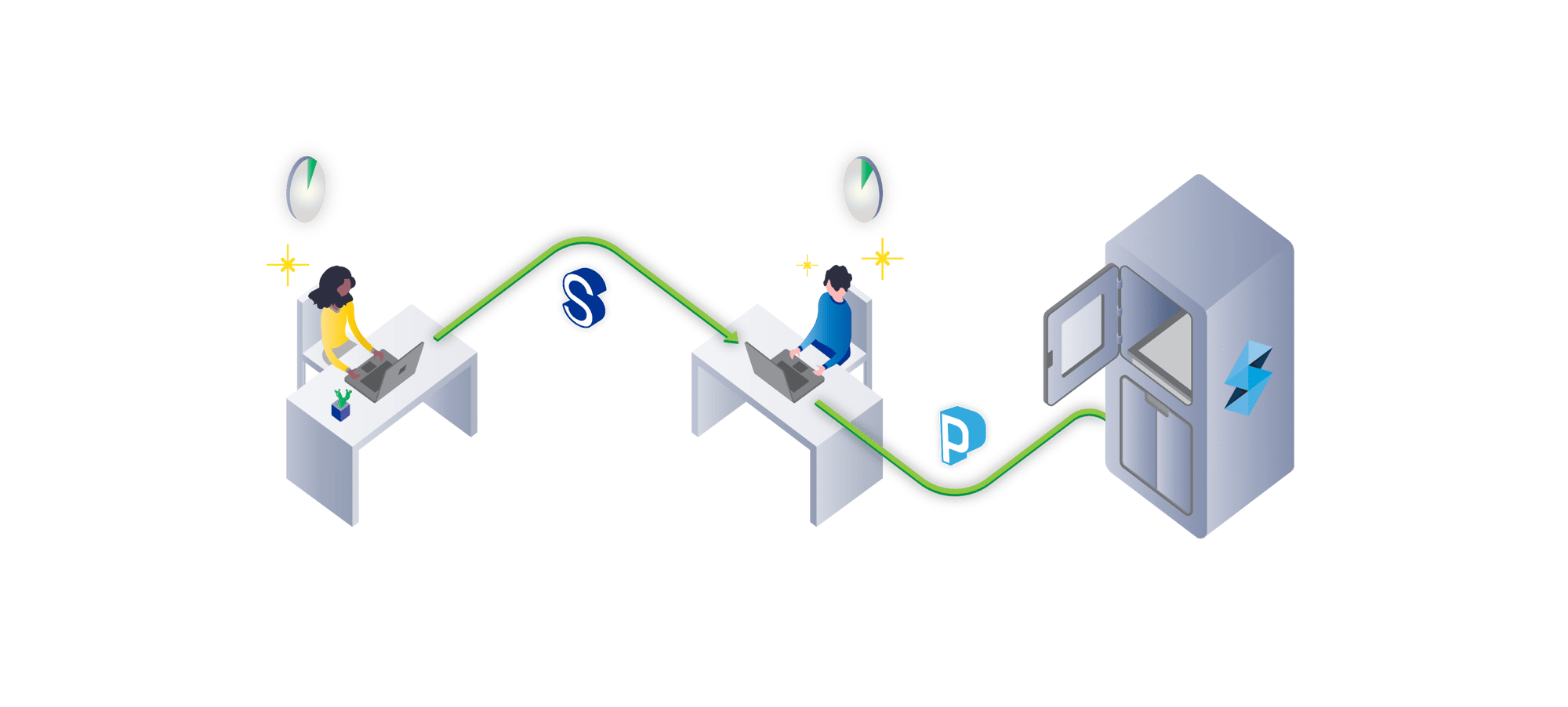

How does it work?

Design your CAD Project

Request a Quote and upload your STL file

3D Print your part with Laser Lines

Receive Your High Quality Part

Frequently Asked Questions

Here are some most often asked questions - If you didn't find your answer please message parts@laserlines.co.uk directly.

What format should I send files in?

Files can be supplied to us in any native 3D CAD format. Our printer software will import most file types. (.stp) file is the preferred format.

What are the payment options?

Payment terms are typically 30 days but are subject to approval from our accounts department.

How much is it going to cost?

Cost depends on the size, technology and material. Upload your files and send us the specifications to get a personalised quote.

How do I choose the right material?

There is an extensive range of materials across various additive manufacturing processes. Please provide as much information as you can, regarding your project / application and we will advise on the most suitable material and process. Alternatively, contact us to discuss the various options.

Meet Our 3D Printing Bureau Team

Richard Hoy

Applications & Additive Manufacturing Manager

Max Farnell

Applications Engineer

Nathan Freeman

Applications Engineer

Hannah Veltom

Applications Technician

Get Your Quote

Please provide all data in 3D CAD format and as much information as possible about your project / application.If you still have some questions give us a call on 01295 672599 or email parts@laserlines.co.uk if you need any help or advice.